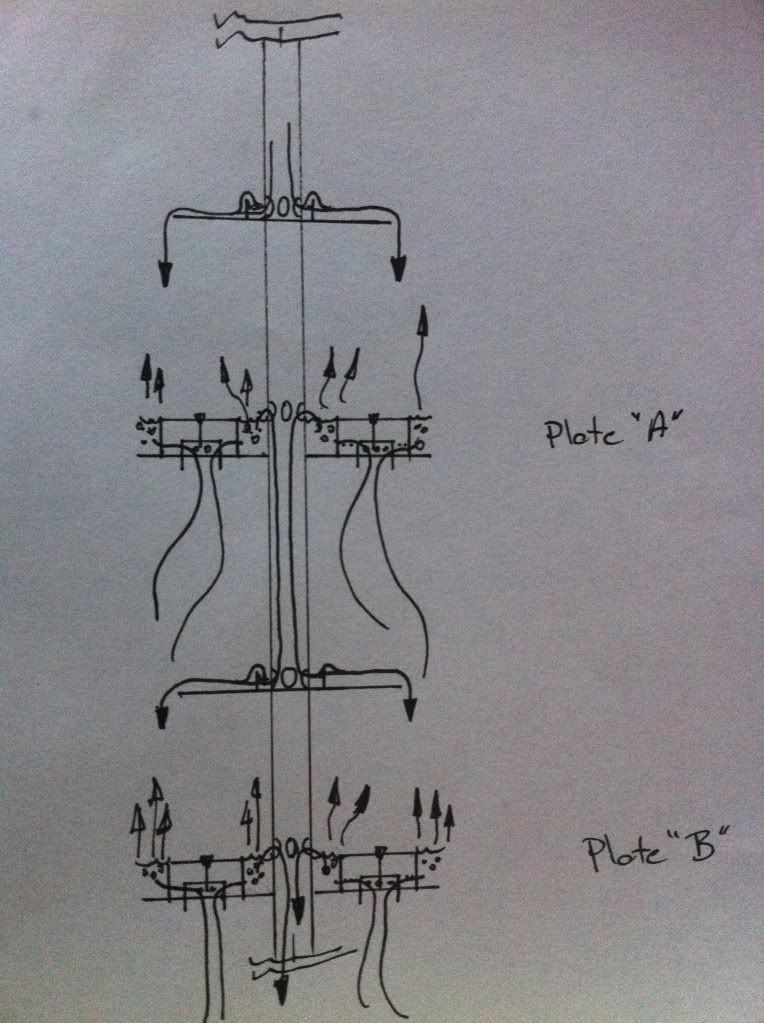

You will have to imagine the 4" column in the drawing

This is not my idea. I don't remember where I saw it, sorry in advance for the lack of credit to who ever I stole the idea off.

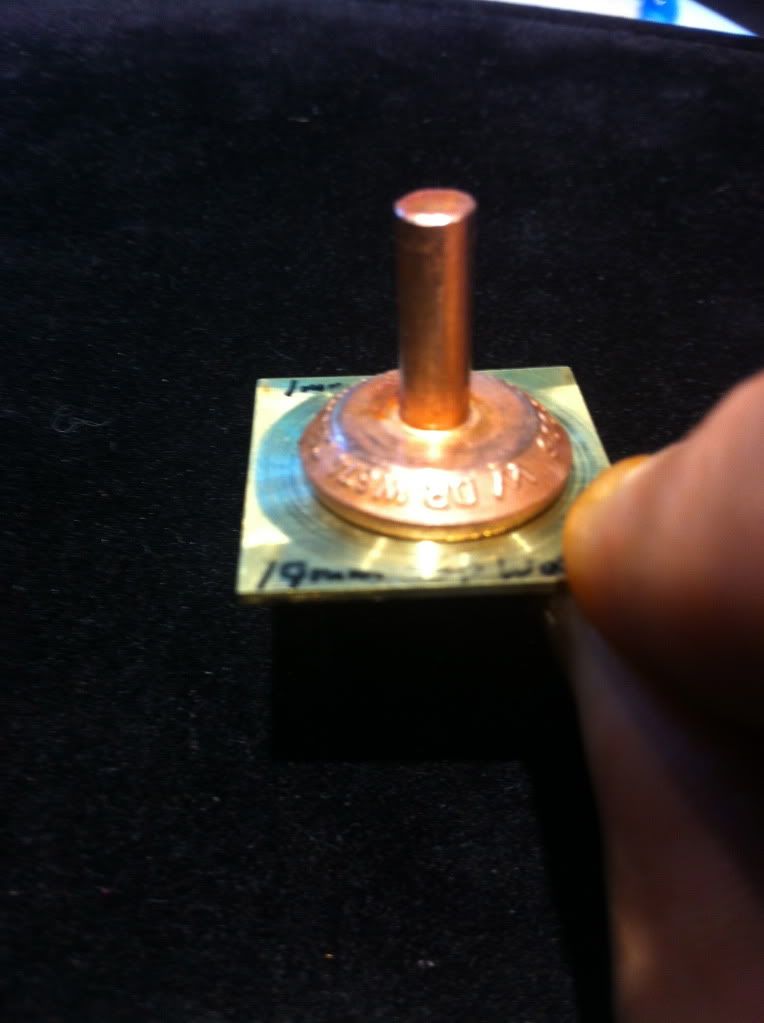

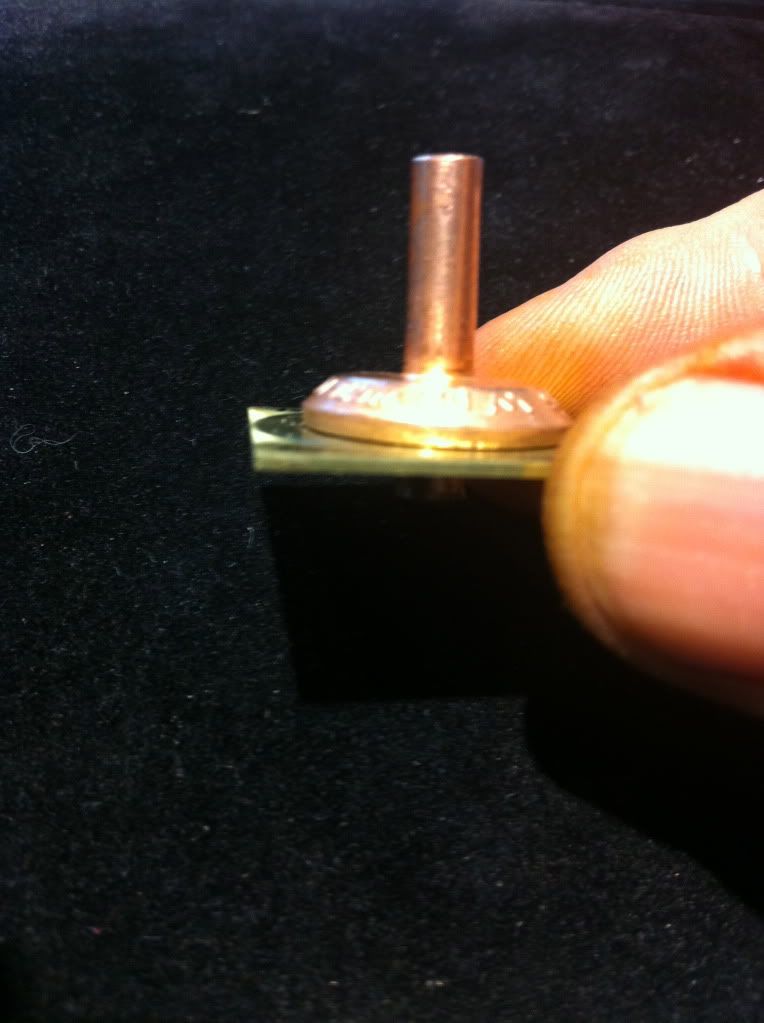

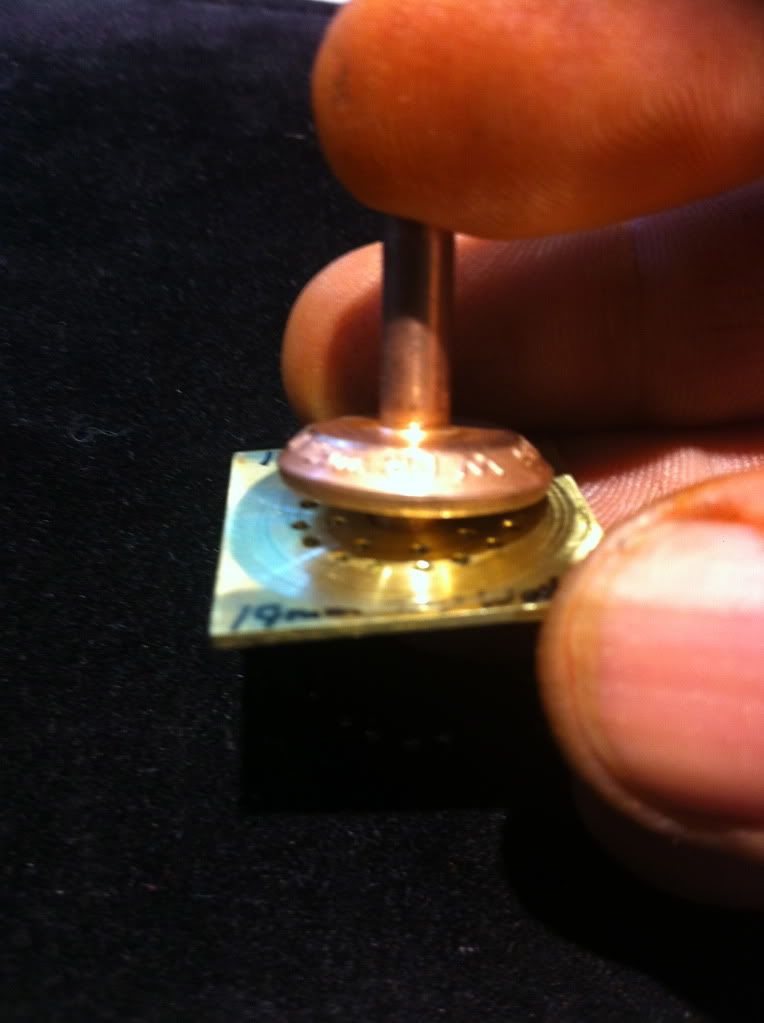

I plan to use (6-8) 1/2" & 1" end caps for the bubble caps per plate. The outer cap screwed to the inner cap like the AC are.

What size holes and how many should I use on the out caps?

I thought I would solder the 1/2" cap to the plate.

I was thinking a 3/4" downcomer would do the job?

The downcomer liquid would exit on a 3" plate to rain over the bubble caps. There is a weir at the tube exit.

What have I forgotten?

Ideas?

5 Star Store

5 Star Store Community Guidelines

Community Guidelines Newbies Corner

Newbies Corner Recipes

Recipes AD search

AD search