by Modernity » Sat Mar 17, 2012 7:56 am

by Modernity » Sat Mar 17, 2012 7:56 am

Maheel & WineGlass,

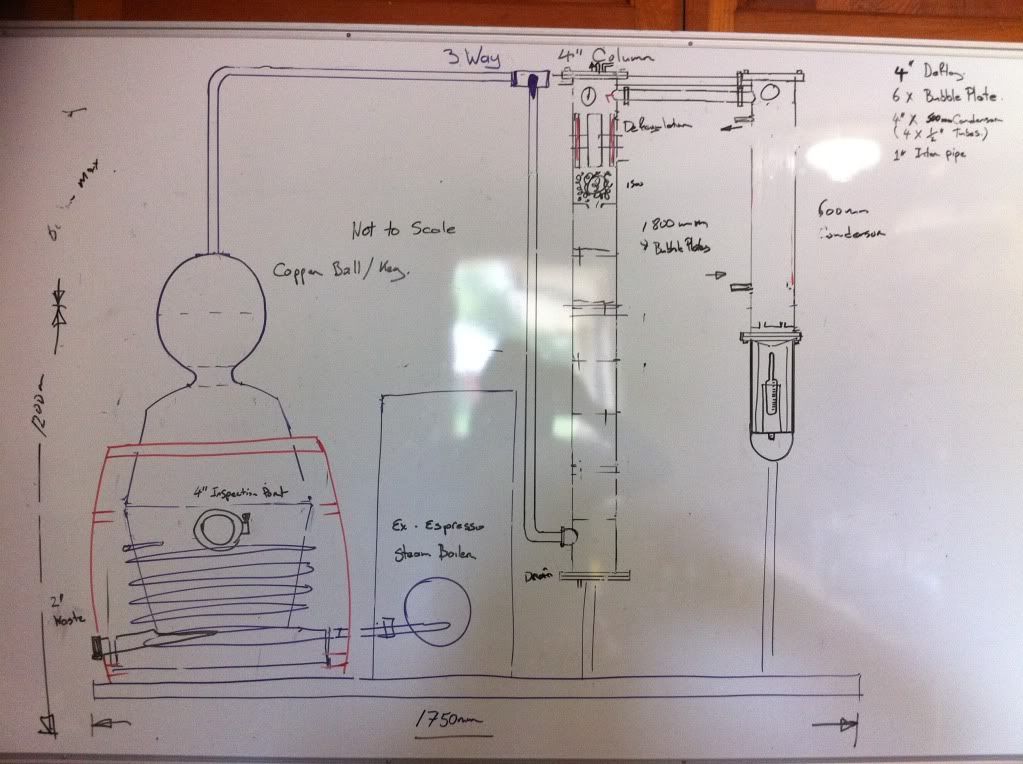

I don't believe there will be high volumes of water (cooled steam) exiting the heating coil so I have not planned to recycle it. Due to the temp of the water I didn't want to feed it back into the espresso boiler because of the feed pump. If later I decide to recycle i may include cooling the water then it will become part of the cooling system.

Espresso boilers are pretty good little setups. They are pressurestat regulated with a internal float valve to maintain water levels. The good thing for US is they are loaded to lime scale after 5-10 years and the whole machine is replaced. SO they can be found fairly cheap "not working". This statement most often refers to the pricy PID's they use.

This is how it works:

Middle of the busy morn shift the machine stops working, :handgestures-thumbdown:

the cafe owner urgently calls up the espresso tech guy, :violin:

he arrives and fault finds the PID as the problem, :handgestures-thumbupleft:

Tech guy hands the cafe owner a $600 quote, :violence-stickwhack:

Cafe owner turns white and tech guy tells him to call coffee bean supplier,

the cafe owner calls the coffee bean supplier and cries poor, :crying-blue:

Coffee bean supplier turns up with nice new espresso machine and a slightly inflated coffee bean whole price on a 3 year contract and everybody is a winner (baby) :teasing-neener:

The other bonus is the crappiest looking espresso machine still comes loaded with nice boiler, copper fittings, needle valves, pressure gauges, pump, etc.

5 Star Store

5 Star Store Community Guidelines

Community Guidelines Newbies Corner

Newbies Corner Recipes

Recipes AD search

AD search