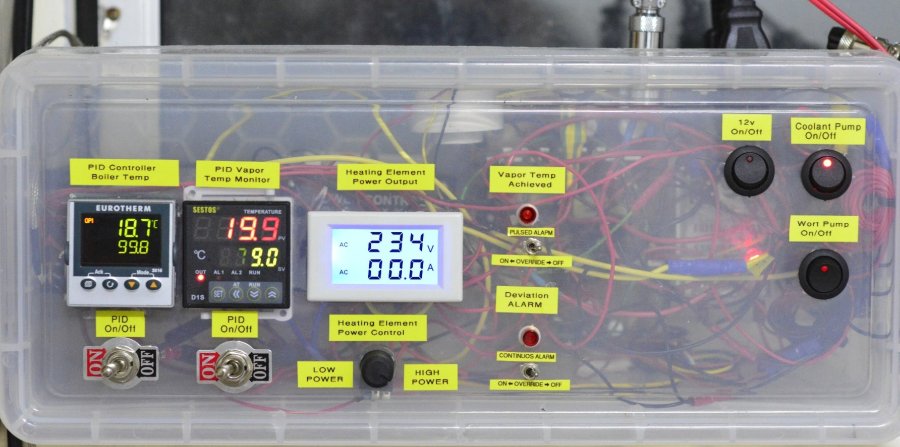

So basically, as you can see from the photo above, it consists of 4 mains parts.

1 - A programmable PID controller for the heating elements

2 - A Heating element power controller

3 - A vapor temperature monitor

4 - Coolant, fans and pump switches and a wort pump switch.

5 - A temperature data logger

Item 1 has a custom program installed that turns on the heating elements and once the wort reaches near boiling point (aprox 80 degrees for the abv I brew) it turns on a pulsing alarm to tell me to go check on the system. At the same time it turns on the coolant pump which is operating off 12v supplied by a computer power supply installed into the controller. At this time Item 2 allows me to control the amount of power being output by the heating elements (anywhere between 4800W and aprox 100w). The PID is then also programemd to switch off the element and turn on the alarm once the wort has reached 98.5degrees (which is where I usually stop my run).

The second PID (item 3) is used to monitor the vapor temperature and sets of a horrible loud alarm should the temperature of the vapour reach outside predetermined parameters (usually >79degrees C).

Note that both alarms have override switches which allow me to turn off the alarm sound but leave the LED illuminated.

The data logger is there so I can check the run afterwards and ensure that the system remained within the desired temperatures. This part is actually somewhat redundant now that I have the controllers installed. It was more used during the testing phase of the build.

Now I know some of you will say that it loks like a birds nest of cables inside. Please note this this build has only been running for a few months and I have not done much cable management inside to allow for easy changes as the build progressed.

So far the system has been operating great and has allowed me to do other things while a run is going and not have to check up on the system constantly. Next build will be an automated cutting machine that will change collection vessels along a run.

5 Star Store

5 Star Store Community Guidelines

Community Guidelines Newbies Corner

Newbies Corner Recipes

Recipes AD search

AD search